Lobe Pump Wafer Baking

- On December 21, 2021

Jupiter Mitra Setia (JMS) incorporates a specialised lobe pump system as a key feature in its wafer-baking machinery. This technology allows the machine to handle two different food materials simultaneously—such as dough and flavour mixtures—while maintaining highly accurate dosing and flow precision. As a result, production becomes more consistent, efficient, and controlled, especially for premium wafer products that require uniform thickness and taste distribution.

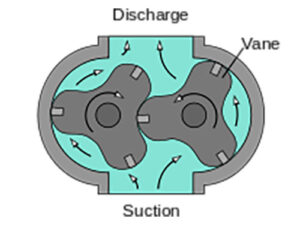

A lobe pump operates in a similar way to an external gear pump, where fluid is transferred around the inner casing. However, unlike external gear pumps, the lobes in a lobe pump do not make physical contact. Their movement is synchronised through external timing gears located in the gearbox. Because the pump’s shaft-support bearings are positioned outside the pumped product zone, the system experiences reduced wear, lower noise levels, and improved hygiene. This design also minimises shaft deflection and helps maintain stable performance, making it ideal for food-processing applications where precision and cleanliness are critical.

Lobe pumps are widely used in food-processing applications because they can handle solid particles gently without damaging the product. Compared to other positive displacement pumps, they are capable of pumping larger particle sizes, making them ideal for mixtures containing nuts, crumbs, or other inclusions. Since the lobes do not make physical contact and the internal clearances are wider than those in other positive displacement pump designs, lobe pumps can also process low-viscosity liquids, although their performance may be slightly reduced under such conditions.